In today’s rapid development of e-commerce, cartons are not only a carrier for transportation, but also an important medium for brand delivery. For merchants or individual users, mastering the basic classification of cartons and how to assemble cartons is an important part of saving costs and improving efficiency. If personalized design can be incorporated into the assembly process, brand recognition and user experience can be further enhanced.

This article will start with the classification of cartons, and analyze the usage scenarios and assembly skills of various types of cartons in detail. At the same time, it will share how to incorporate personalized elements into packaging to help you create a practical and unique carton solution.

How to put together a cardboard box: Multi-dimensional classification of cartons

Understanding the classification of cartons is the basis that must be mastered before assembly. According to different uses and needs, cartons can be divided from the following dimensions:

1. How to put together a cardboard box: Classification by size

Small cartons: suitable for packaging and transportation of small items such as jewelry and mobile phone accessories, and a common choice for e-commerce express delivery.

Medium cartons: widely used for packaging of medium-sized items, such as books, clothing, and daily necessities, and are commonly used cartons for moving.

Large cartons: used to pack large or heavy items, such as small appliances, office supplies, etc., commonly found in the industrial and wholesale fields.

When choosing the size, it is recommended to choose a close-fitting size according to the actual volume of the item to reduce the amount of cushioning material and reduce transportation costs.

2. How to put together a cardboard box: Classification by shape

Square cartons: stable structure, easy to stack, suitable for the transportation of most conventional items.

Rectangular cartons: specially designed for long strips of items, such as yoga mats, lamps, etc.

Irregular shaped cartons: tailor-made for special items, usually need to be combined with internal support structures to prevent damage to the items during transportation.

3. How to put together a cardboard box: Classification by material

Ordinary cartons: single-layer corrugated structure, low cost, suitable for short-distance transportation or one-time use scenarios.

Wear-resistant cartons: double-layer or triple-layer thickened corrugated paper, strong pressure resistance, suitable for heavy packaging and multiple use.

Waterproof cartons: The surface is covered with waterproof coating or PE film, which can prevent moisture and splashing. It is suitable for items that are easily affected by moisture, such as food, fresh food, and electronic products.

4.How to put together a cardboard box: Classification by usage scenario

Moving cartons: Considering load-bearing and stability, the interior usually needs to be reinforced, which is suitable for centralized packaging of daily items.

Express cartons: Strong standardization, often printed with express company logos, easy to sort and identify.

Industrial cartons: The focus is on strength and protection performance, mostly used for the transportation of mechanical parts, bulk commodities, etc.

5. How to put together a cardboard box: Classification by processing method

Automated cartons: Produced in batches by machines, suitable for large-volume orders, and high efficiency.

Handmade cartons: The first choice for small batches and personalized customization needs, suitable for gift packaging, limited edition products, etc.

6. How to put together a cardboard box: Classification by finished product status

Flat cartons: Unfolded state, small space for transportation and storage, requires manual or mechanical folding and forming.

Folding cartons: After partial pre-folding, assembly is faster and suitable for daily packaging of e-commerce.

Fully assembled cartons: Finished cartons are ready to use out of the box, suitable for urgent shipments or offline retail terminals.

How to put together a cardboard box: steps and techniques

Mastering the correct assembly techniques can not only save time, but also improve the carrying capacity of cartons.

Step 1: Confirm the direction and opening

Spread the flat carton flat on the flat ground, confirm the position of the bottom of the box, distinguish the bottom and the top, and avoid sticking the wrong tape or opening the wrong seal.

Step 2: Fold the bottom and reinforce

First fold the smaller baffles on both sides of the bottom inward, and then align the two large baffles. Use sealing tape to stick along the middle seam, and reinforce the bottom in a “cross” or “I” shape to avoid cracking when bearing weight.

Step 3: Load items and protect with fillers

After the items are placed in the carton, bubble bags, kraft paper, corrugated inner trays, etc. can be used as cushioning materials to prevent shaking and collisions.

Step 4: Seal and label

The top sealing method is the same as the bottom. After completion, remember to affix item labels or shipping information for easy logistics tracking and identification.

How to put together a cardboard box: How to show personalized carton style?

In addition to basic functions, more and more companies are beginning to upgrade brand communication and customer experience through customized cartons. Here are some practical suggestions:

1. Customized printing and brand identification

Printing brand LOGO, slogan, social media information, etc. on cartons is the most common way to display brands. You can choose environmentally friendly inks, hot stamping, UV printing, etc. to enhance visual impact.

2. Unique structural design

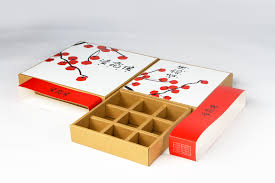

Such as drawer-type, clamshell, double-layer structure, etc., not only enhance the user’s unboxing experience, but also enhance the packaging function. For example, a high-end tea brand uses a book-style carton structure, which makes consumers feel like opening a book when unpacking, enhancing the sense of ritual.

3. Environmentally friendly materials and reusable design

The use of environmentally friendly materials such as recycled paper, bamboo pulp paper, and degradable tape helps to establish a sustainable corporate image. At the same time, designing reusable cartons, such as folding storage boxes, toy storage boxes, etc., is also popular with consumers.

4. Creative unboxing experience

“Unboxing” has become a way of communication. Add thoughtful details, such as thank-you cards, personalized illustrations or QR code interactive pages, so that consumers can feel the warmth and care.

Conclusion: Packaging is brand, starting from assembly

Whether it is daily moving, commercial delivery, or brand packaging display, cartons are indispensable carrying tools. Correct assembly of cartons can ensure transportation safety, and personalized design is a plus for brand communication.

Today, as the use of cartons becomes more and more diverse, from selection to assembly to aesthetic design, every step is worth our consideration. If you are still using the same old carton packaging, you might as well try to add personalized elements from today to make packaging a part of the product.

Post time: Jun-12-2025