What would you like to know more about us?

Established in 2009, Dongguan Fuliter Paper Products Co., Ltd. is a professional paper printing and packaging manufacturer. We are mainly engaged in one-stop packaging design, research and development, and production of high-quality cigarette boxes/custom pre roll boxes, food boxes, tea boxes, flower boxes, hat boxes, wine boxes, plastic Jars/Cans packaging, mailer paper boxes, gift boxes, cardboard paper boxes, PVC boxes, PVC labels/paper label,cigar label and instructions Companies and factories specializing in the production of such products have a complete and scientific quality management system. We are located in Humen, Dongguan, with convenient geographical location and transportation. Professional workers and advanced equipment We have complete production equipment, including 36 advanced printing machines, excellent management and assembly line operation. The company covers an area of more than 5900 square meters and has more than 130 skilled employees. We also have professionals in engineering, R&D, marketing and quality control departments. Our R&D team adheres to the business philosophy of "helping global companies build world brands", and is able to independently design and develop new products and new box types, and meet the pre roll boxes wholesale OEM and ODM requirements of domestic and foreign customers, thus providing quality assurance and service.

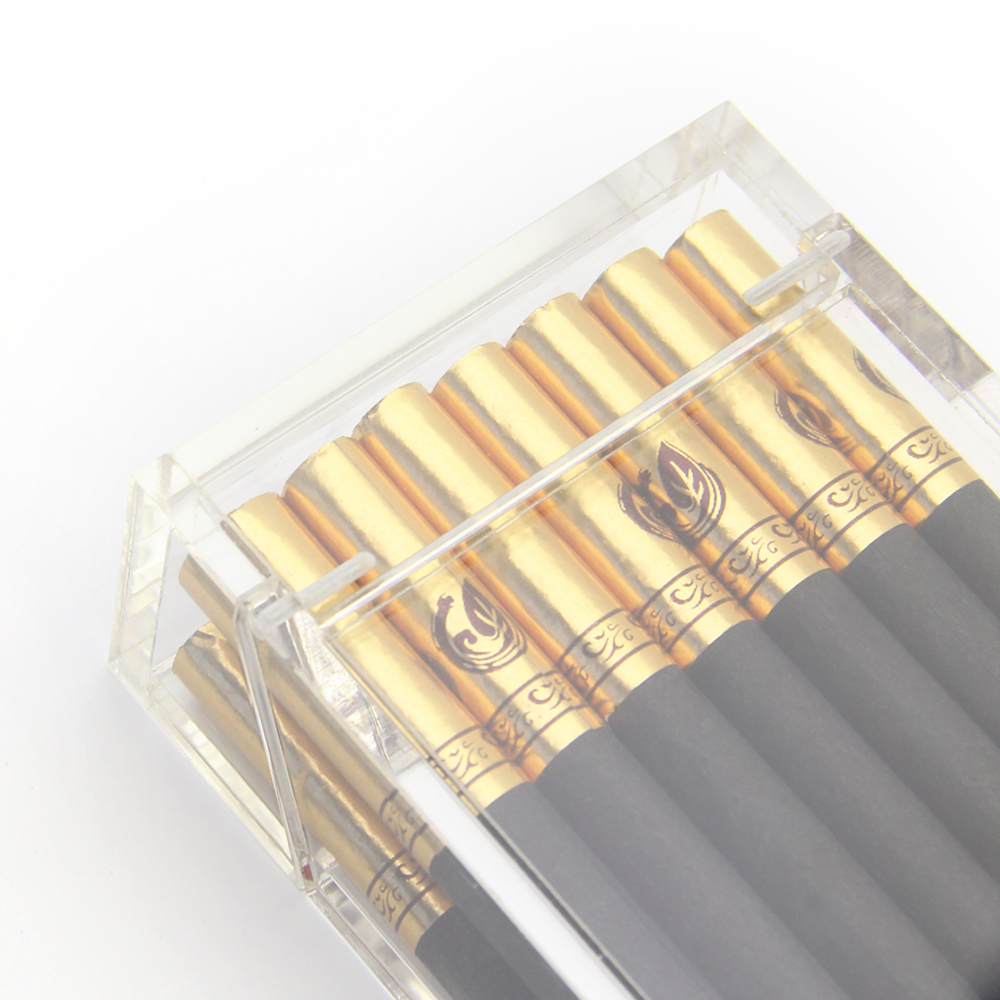

We have been in the field of printing and packaging for 14 years, but we have been researching and focusing on the field of pre roll box packaging for more than 10 years. Have enough experience to make good packaging and ideal packaging for custom cigarette box products. As you know, cannabis box are special packs, which are different from ordinary packs. Not all plants are good at this. You are our important customer in the cigarette field, and we hope to create a one-stop service for this field. And develop more related professional services for this purpose.

At the same time, we also have a professional and experienced team to provide customers with one-stop service. For example, the sales QC team can provide quality assurance, the logistics team can provide transportation arrangements, can provide the best price and DDP door-to-door service, the production team can provide high-quality cardboard cigarette boxes packaging and strong outer boxes, and purchase peripheral accessories required by customers ( such as smoke machines). Herb Grinders, cigarette holders, pre-rolled paper, custom ribbons, hemp CBD oil bottle, plastic jars etc.), the QC team can provide quality assurance, and the logistics team can provide shipping arrangements.

Design drawings can also be provided for you. FULITER's design team focuses on your design concept and will accompany your packaging project from initial idea to implementation. FULITER designers will give you some good ideas and suggestions during the design process. They can also create 3D designs for you to see in action. So that customers can see their designs on the 3D hemp oil box/hemp cardboard boxes more intuitively and clearly.

Our company's corporate culture and business philosophy: Adhere to the "specialization and scale" development strategy, implement the market development strategy of "high-end customers, high-end products", create good products to achieve customers, establish a good mechanism to achieve employees, and respect every step of the customer Divide money and create value for customers with packaging.

Service tenet: customer-centric, honest life, rigorous work, win-win business.

Corporate vision: To build a modern packaging base with international influence in the new century with a new modern management model and development strategy, so that packaging can help products open up the market decently.

Core values: Create value for customers, create opportunities for employees, create benefits for enterprises, and create employment for society.

Our mission: Adhering to the consistent style of pursuing leadership in technology, quality, cost, responsiveness and supply in the past, constantly analyzing market trends, understanding the latest information, conducting product research and development and updating, and providing customers with fashionable mold designs, Develop and manufacture to create the safest, environmentally friendly and valuable packaging.

In 2013, according to the market demand, it is necessary to pay attention to environmental protection, use of recyclable materials and sustainable development, not only to comply with the regulatory requirements of employees, consumers and communities. By prioritizing sustainability, we protect employee health, employees, consumers and communities. Greatly improve the utilization rate of raw materials, green environmental protection and pollution-free, by giving priority to sustainable development, we can protect the health of employees, improve product quality and reduce the negative impact on the community. Expand the production scale, introduce personnel and technical equipment, and improve the supporting paper Box printing deep embossing, embossing, partial UV and bronzing processes, leather box luggage sewing process, wooden box painting and silk screen printing process, etc. The existing production base covers an area of 6,000 square meters and employs 200 people. The company adopts fully automatic production equipment: various types of German printing machines, automatic die-cutting machines, automatic bronzing machines, automatic world box machines, automatic leather shell machines, automatic lamination machine, automatic laminating machine, automatic slotting machine, automatic box gluing machine, automatic boxing machine, automatic placement machine, automatic machete machine, laser die cutting machine and various supporting equipment, with a daily production capacity of more than 80,000 sets of gift boxes, We have a Heidelberg five-color printing machine, which is a printing device that can print five colors at the same time. Its working principle can be simply described as a series of steps to precisely transfer five colors of ink onto the printed material.

Five-color presses usually have five ink cartridges, each containing cyan, magenta, yellow black, and white inks. Each ink cartridge is connected to the printing press's nozzle, which has many tiny orifices. When the printing machine starts to work, it will open the corresponding ink tank according to the need, and control the opening and closing of the nozzle holes on the nozzle to control the ejection of ink.

Next, the printer places the printed material on a flat printing plate. There will be some uneven areas on this printing plate, which correspond to the images and texts to be printed. When the printing press starts to work, it will place the printing plate on top of the printing material and control the printing plate through a series of transmission devices. the mobile

During the printing process, the printing machine will select the corresponding ink cartridge and nozzle according to the required color. When the nozzle is opened, the ink will be sprayed into the concave and convex areas on the printing plate. Due to the certain pressure between the printing plate and the printing material, the ink will be transferred from the concave-convex area to the printing material to form images and characters.

However, since the five-color printing machine needs to print five colors at the same time, multiple jets are required during the printing process. This is achieved by controlling the switch of the nozzle and the injection time of the ink. After each jet, the printing machine moves the plate a certain distance so that the next color of ink can be jetted to a new area on the plate.

In order to ensure that the five colors of ink can be accurately ejected onto the printing plate, the printing press also needs some calibration work. For example, it uses sensors to detect the position of the extruder and the amount of ink ejected to ensure the accuracy and consistency of each ejection

Inks on printed materials take time to dry out. Therefore, the printed material needs to go through a drying process after printing to ensure the quality and durability of the printing effect

The five-color printing machine can simultaneously print images and characters in five colors by controlling the jetting of nozzles and ink, as well as the movement and calibration of printing plates. Its working principle is simple and effective, bringing higher efficiency and richer color choices to the printing empty cigarette box industry. It is far ahead in the same industry. Direct factory large-scale production, complete production equipment and technology, reducing intermediate costs and waiting time

The performance configuration of Heidelberg five-color machine is introduced as follows:

1- Sheet Feeder

The front drop can be adjusted individually, and the shell gauge can be adjusted steplessly to achieve precise registration. The GT0 52 is equipped with electromechanical and ultrasonic double-sheet monitors, so as to ensure that any material brush will not travel to the electromechanical of the sheet. The monitor makes the production more safe and reliable, even if opaque or transparent materials are used, the handling of all materials is extremely flexible, and the printing format and substrate can be changed quickly and easily.

2- printing unit

The design of h egg GI0 52 is anti-virtual, and the coating surface on it proves the long-term working life of the drum, and the extremely small production tolerance in the rolling process adds to the smooth travel of the problem. The unique rolling pillow to rolling pillow pressure of Heidezhan ensures the precise rolling between the printing plate cylinder and the rubber cylinder and the accurate transfer of dots.

3- Alcohol-free continuous dampening system (DDS IID

It is the future development trend to not contain snow in the oral liquid. Substitutes can reduce the impact on health and pollution, and save costs. The continuous dampening system of Yinlu G052 has been improved to the maximum chemical energy. A combination of live and meat substitute knots, water drift and Xunchuang is used to achieve the balance of ink and ink. When the printing machine stops, all the plate cleaning plates will be lifted off the printing plate automatically. After the work is completed, the cleaning plate and the delivery system can be cleaned in real time, and there is no need to leave the cleaning plate and clean it separately. This saves time and the press is ready for the next job more quickly.

4- Large capacity ink delivery system

5-Paper overturning device

In the current G1052, each sheet has been passed through Tianhe once to achieve 100% standard reliability, the back of the sheet is tightened, and the paper is reliably written in strips, the small peaks on the letter, the flat sheet and the street paper, 3 turns can be performed after the first or second printing unit. To switch between simplex and flip mode, only a few simple seats are required

6-Paper delivery device-strong flexibility, easy to combine

Thanks to the use of sheet length brakes, spacers and indirect length brakes, each sheet can be reliably saved on the receiving end. As a result, neat stacks can be transported away or sent to post-press immediately. The special spraying device can prevent the paper that has just been loaded from being checked when it is moving. The long-term stop and the degree of powder spraying can be adjusted individually according to different jobs. Because of the original settings of coding and beating rate, you can have Various washing options and ratios, you can choose according to the new market trend, water-packed one-person washable glazing list. Also configure other options

7-glazing unit

Relying on an extensive packaging cooperation network, we cooperate with manufacturers of various packaging materials, and use Jinyi's professional resources of packaging engineers, procurement engineers, and logistics engineers to design personalized solutions to ensure that customers enjoy one-stop service. VMI supplier inventory management: implement network-like management through supply chain process control (VFC), undertake timely packaging material procurement and supply responsibilities for customers, and ensure JIT supply services. Economical second-party procurement, professional supplier inventory management, highly competitive supply chain services, reducing customer packaging costs and increasing product added value to continuously meet and exceed customer expectations

The technique of achieving quality optimization and reducing scrap rate through technological innovation of cardboard and carton; through the use of advanced digital equipment and solutions, it saves tedious processes such as plate making, imposition, and color correction, and wins the favor of customers in the small and medium batch printing and urgent mail markets. Case, can provide a variety of different specifications of cigarette case printing, box packaging line, to meet the diverse needs of customers, create new value for customers.

Post time: Aug-21-2023